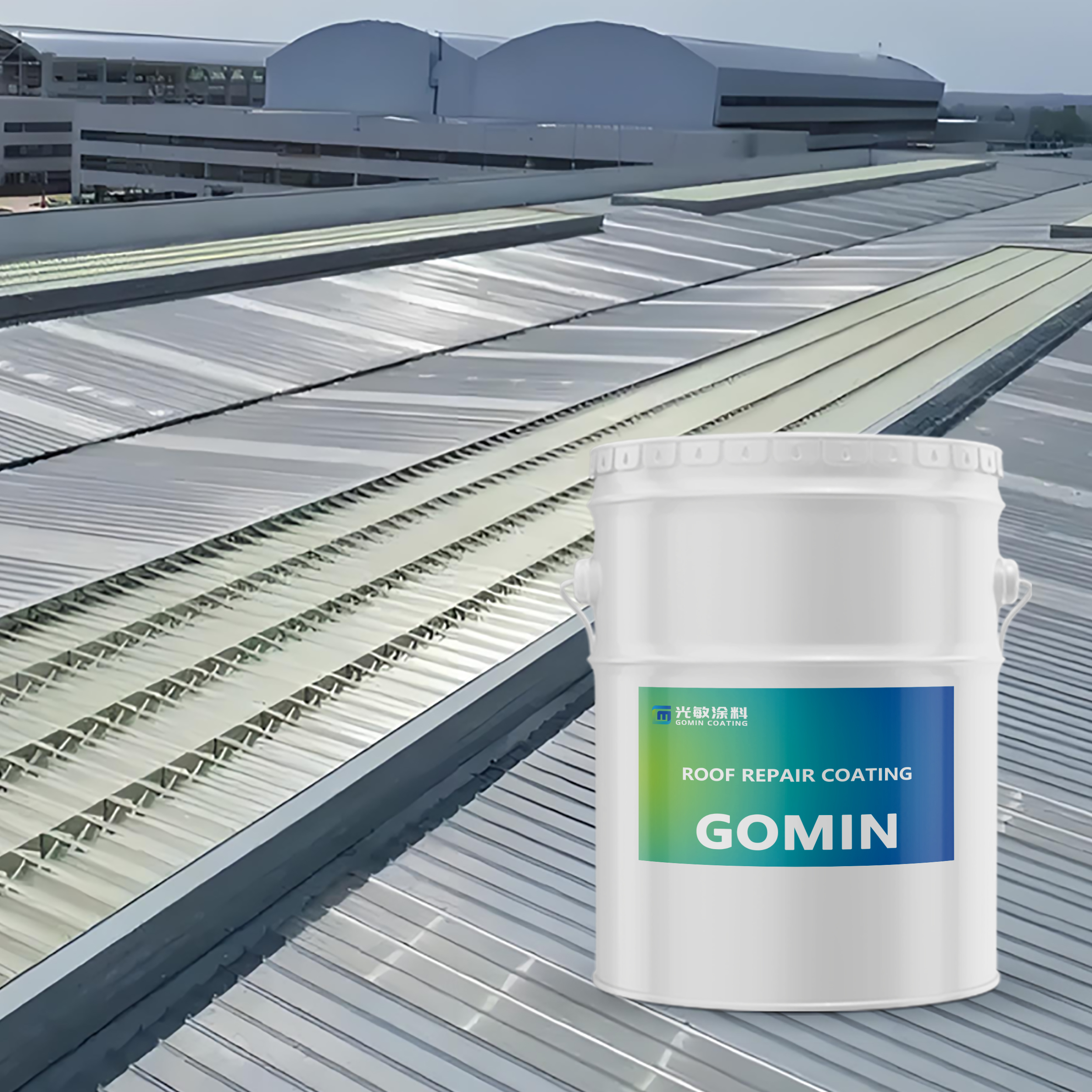

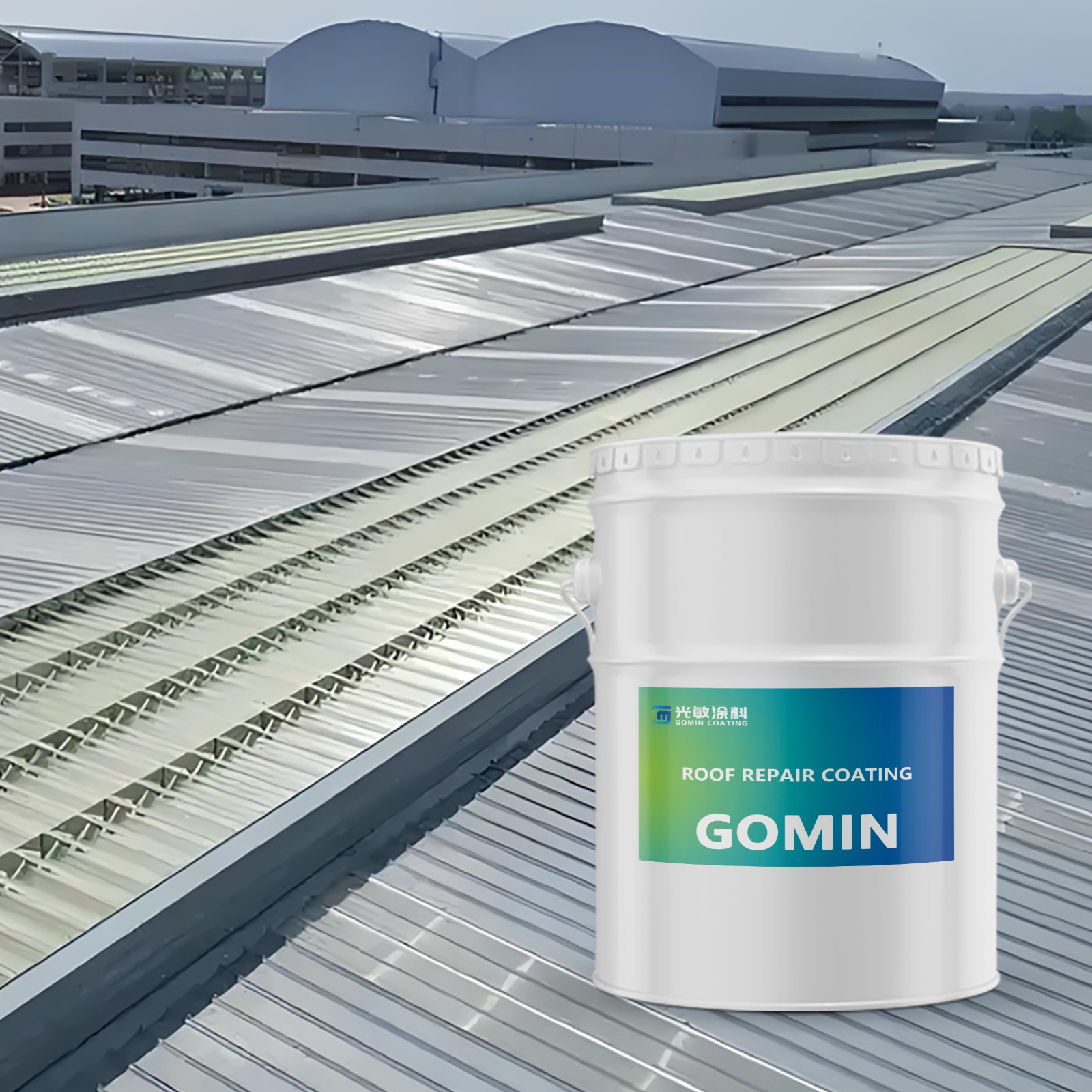

GM-XF High-Performance Acrylic Roof Coating – Waterproof, Anti-Rust, UV Reflective for Metal Roofs

Brand GOMIN

Product origin China

Delivery time 45days

Supply capacity Consistent and reliable long-term supply

Acrylic coating offers strong adhesion, UV resistance, and waterproof protection. It’s fast-drying, eco-friendly, and ideal for restoring and protecting metal roofs from rust and aging.

Metal Roof / Steel Structure Solutions

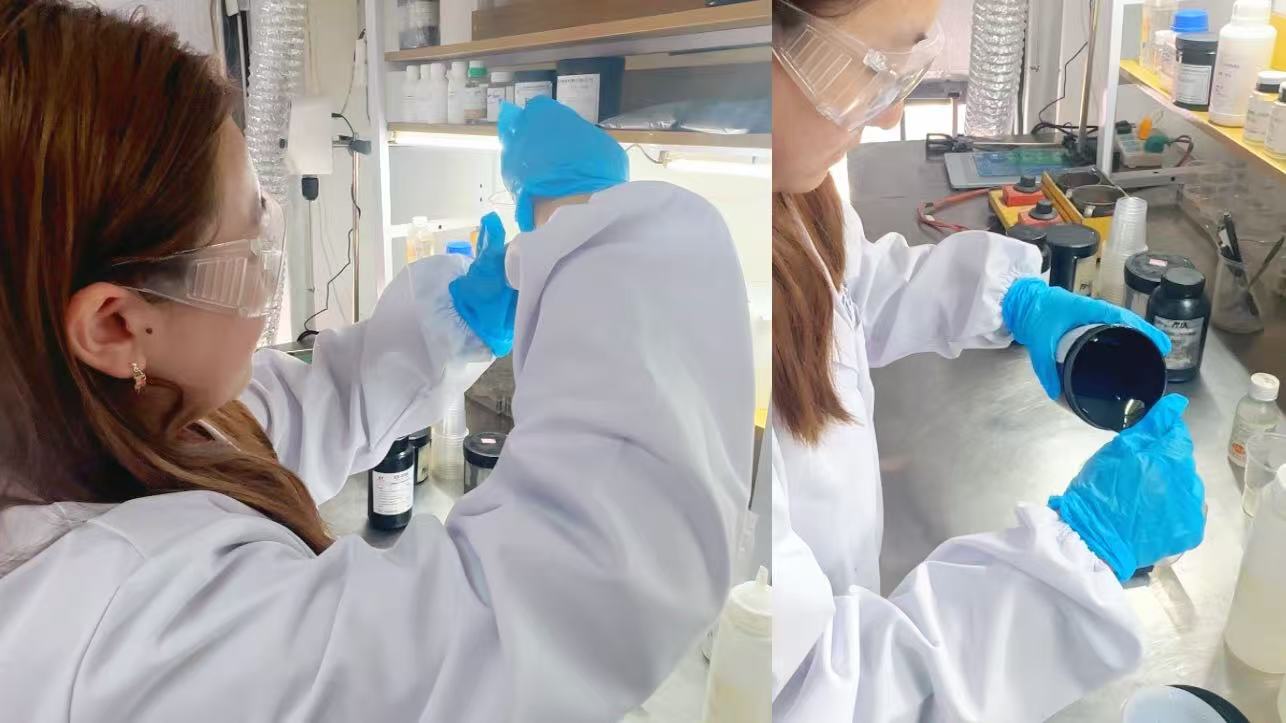

GM-XF Acrylic Elastic Coating is a high-performance product made from premium acrylic-silane copolymer elastic emulsion, various additives, and UV-reflective materials. It is non-toxic, harmless, and environmentally friendly. Custom colors are available to meet customer needs, and it offers easy application and maintenance with excellent adhesion to metal surfaces.

This coating provides moisture resistance, mold prevention, non-peeling, non-cracking, enhanced gloss, strong stain resistance, washability, and high coverage. It also features fast curing, aging resistance, high-temperature tolerance, cold resistance, and UV reflection.

GM-XF Acrylic Elastic Coating is suitable for various metal structures, including houses, workshops, warehouses, and factories. It delivers exceptional waterproofing, anti-corrosion, and rustproofing effects, especially for complex roofs or metal structural components.

Advantages of Metal Roofs Coating

Innovation

Our light-sensitive specialty coating emphasizes innovation. This roof-specific product ensures full coverage, even in corners, with zero rust gaps. Compared to traditional anti-corrosion paints requiring refinishing every 3-5 years, significantly reducing maintenance costs.

Exceptional Performance

Outstanding environmental adaptability—providing lasting protection even in extreme climates:

No sagging in high temperatures

No cracking in freezing cold

50% higher UV reflectivity

Over 3x longer lifespan

Convenient Application

Ready to use immediately, saving time and labor. Unlike oil-based paints that require 24 hours to cure, this product dries to the touch in just 1 hour, enabling rapid deployment and reduced project costs.

Value

A single application reduces labor costs, extends service life, and greatly enhances economic efficiency.

Performance Parameters

Item | Topcoat Specification | |

Color (as in container) | Peacock Blue | |

Film appearance | Smooth and even | |

Flow time (No. 4 cup, s) | ≥100 s | |

Fineness (μm) | ≤25 μm | |

Hiding power (g/m³) | 40–150 g/m³ | |

Gloss | 0–90° (customizable) | |

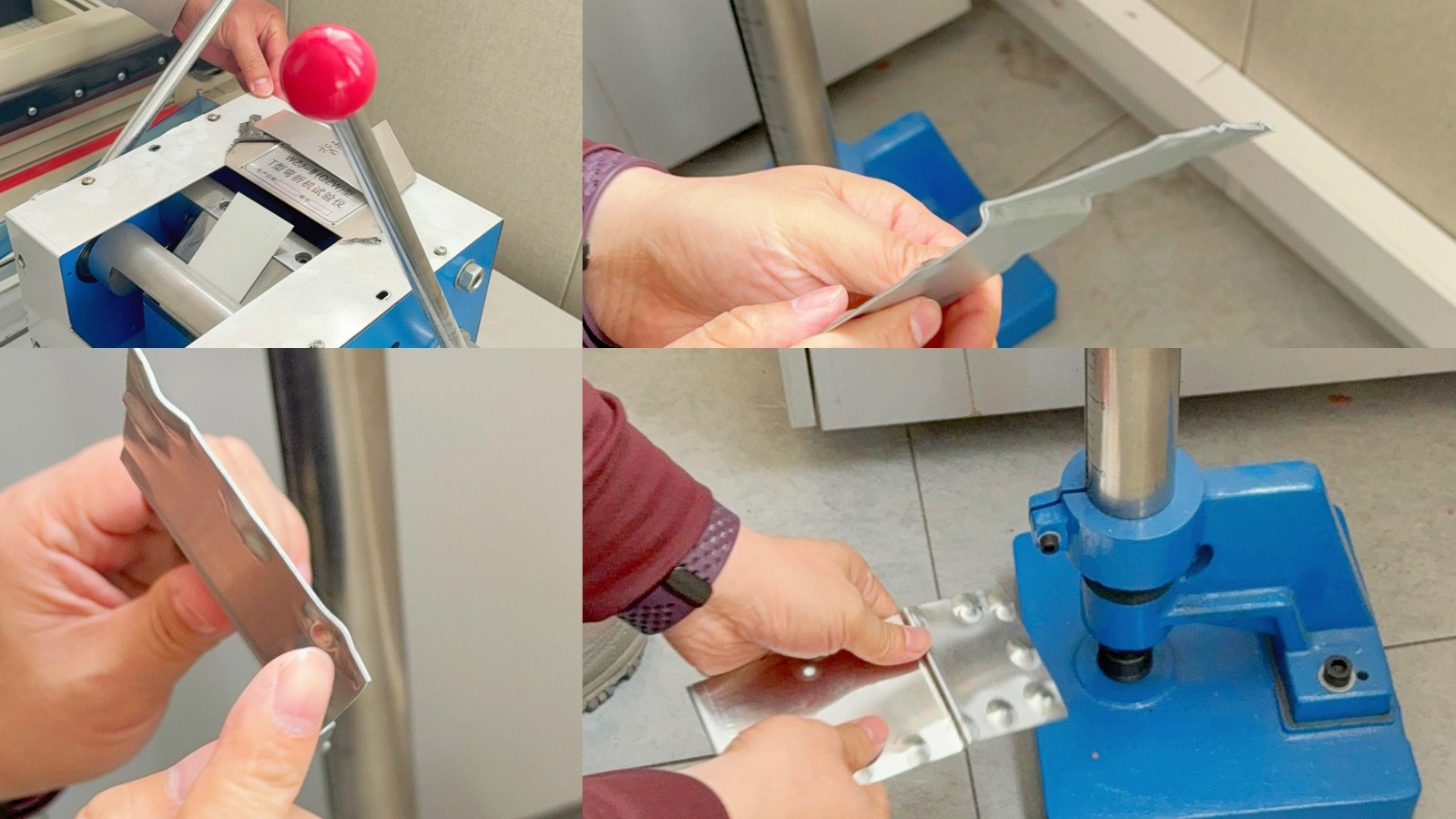

Adhesion (grade) | 0–1 | |

Solid content (%) | ≥35 | |

Impact resistance | Pass (front & back) | |

Bend test (mm) | ≤2 mm | |

Water resistance | 168 h | |

Artificial weathering resistance | 200 h (no blistering, cracking, peeling, or chalking; gloss loss ≤ grade 3; color change ≤ grade 2) | |

Drying time (20°C) | Surface dry(20℃,h) | 1h |

Hard dry(20℃,h) | 24h | |

Baking (h) | 80°C for 40 min | |

*The above data are based on actual formulations and products.

Application Instructions

The following instructions and recommendations are for reference only and may require adjustments based on local conditions.

▊ Substrate Preparation

Thoroughly remove oil, rust, oxidation layers, dust, and loose particles from the metal surface.Rust removal methods: Mechanical abrasion (e.g., grinding wheel, wire brush) or chemical rust removers may be used to achieve a surface cleanliness of Sa2.5 grade (free from visible oil, mill scale, and rust).For existing coatings, sand smooth to ensure no peeling, blistering, or cracking.Wipe the cleaned surface with a dry cloth to ensure it is dry and moisture-free (moisture content ≤8%).

▊ Ambient Conditions

Temperature: 5°C–35°C; avoid direct sun exposure or frost conditions.

Humidity: Relative humidity ≤80%; do not apply during rain, snow, or strong winds.

▊ Application Methods

Method | Instructions |

Brushing | Suitable for small areas or edges. Apply evenly and avoid excessive thickness. |

Spraying (Recommended) | Airless Spray: Nozzle size 0.4–0.5 mm, pressure 15–20 MPa. |

Conventional Spray: Adjust dilution ratio appropriately. Maintain a distance of 20–30 cm from the substrate. |

Precautions

(1) Wear protective gloves, masks, and goggles during application. Ensure adequate ventilation.

(2) Avoid exposure to open flames or high-temperature sources before full curing.

(3) Store sealed in a cool, dry place (5°C–35°C). Protect from freezing or direct sunlight. Shelf life: 12 months.

(4) Reinforce coating or apply sealant in complex structures (e.g., pipe joints, rivets).

(5) Sand and recoat repair areas to maintain coating continuity.

Tear-off Film Coating

Heat Radiation Coating

Glass Thermal Insulation Coating

Thermal Insulation Coating

FAQ

1. Does this acrylic coating offer waterproof and UV-resistant protection?

Yes, our acrylic roof coating is specially formulated to provide excellent waterproofing and long-term UV resistance. It effectively protects metal roof panels from corrosion, weathering, and color fading caused by sun exposure.

2. Is a primer required before application?

While some surfaces may benefit from a primer for enhanced adhesion, many galvanized or previously coated steel roofs can be coated directly after proper surface cleaning.

3. How long does the coating last? Is there a warranty?

Under normal conditions, the coating can last up to 8–10 years with proper application. We offer a product warranty of up to 5 years, depending on the usage environment and application quality.

4. How much area does one bucket cover? How many coats are needed?

Coverage depends on surface condition and application thickness. On average, 1 kilogram covers approximately 4–6 square meters per coat. For best results, we recommend applying 2 coats.

5. Does this coating have reflective or heat-insulating properties?

Yes, this acrylic roof coating includes reflective pigments that help reduce surface temperature by reflecting solar radiation. It can lower indoor temperatures and reduce energy consumption in hot climates.